Church of St. Peter Claver

West Hartford, Connecticut

Opus 85, 2008

Construction Photos

Kent and Lyndon glue up a windchest grid. Each board forms the wall of a “channel” for a single note on the keyboard. There’s a channel for every note on the keyboard.

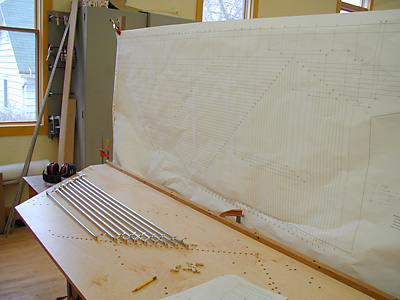

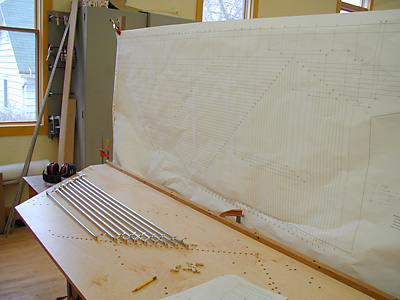

The dividers or “channel bars” have dovetailed ends that match slots cut in the windchest grid frame. Glue is applied to the bars and they are hammered into place.

The toeboards and rackboards are fitted to the completed windchest grid.

Kent uses a router and a special jig to cut the pallet slots. There is a slot for each key on the keyboard.

All of the pallet slots have been cut in this windchest.

A rollerboard being assembled.

Finished rollerboards laid out behind completed windchests.

Bob glues twill tape hinges on the lid of the reservoir.

The reservoir is ready for the rib leather.

Bob has leathered the ribs and is now applying the gussets, the soft leather that cover the corners of the reservoir.

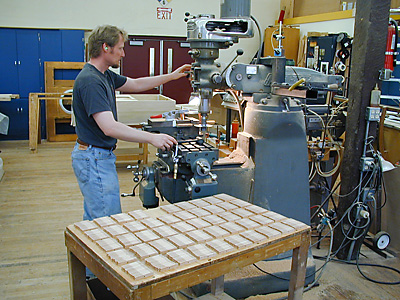

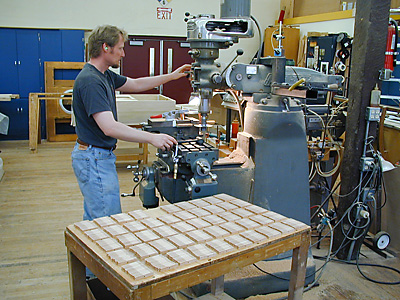

John machines parts for wooden squares.

Just look at all of them!

Kent rips white oak lumber using a power feeder on the Altendorf table saw. These oak pieces will become the horizontal elements in the façade.

These oak strips are part of a framework that forms the backdrop for the façade pipes.

A completed section.

Above each flat of façade pipes is a “crown” consisting of wooden dowels on brass rods that project over the pipes. Each dowel projects a little more than the one below it.

Randy mounts hinges on doors in the lower case.

Finished casework leans against the wall in the erecting room. White oak tongue & groove boards are mounted on poplar subframes.

The console shell. The mechanical action console chassis and drawknob terraces will be installed later.

The Swell expression shades are set up.

The organ takes shape in the erecting room.

A framework of oak pieces lies behind the façade, with toeboards protruding here and there to support the façade pipes.

The façade pipes have been racked.

The irregular hole in the woodwork at the upper left is to allow part of a truss that supports the church’s roof to pass through the organ. The woodwork will be trimmed around the truss when the organ is installed so that it fits exactly.

The back of the case on the Swell side, showing the walkboard.

The console on a cart, ready to be loaded on the truck to West Hartford.

• • •

Installation Photos

The base of the organ is set up. It’s surrounded by pieces and parts laid across the pews. The console shown in the photo just above can be seen on the extreme right edge of the photo.

The organ was designed to miss the heavy roof trusses that are a prominent feature of the church. Kent and Dean Heim stand in the Swell, whose treble pipes are placed under the truss.

The horizontal wooden boards behind the façade pipes have to be individually fitted around the trusses.

A lot of packing material is needed to protect everything en route to West Hartford. The paper and excelsior piled on the left was all recycled from previous shipments.

Op. 85 Home