Installation of Gallery Organ & 32' Diapason

In order to break a lengthy installation into more manageable pieces, and to gain room by moving completed parts out of our shop, we installed Op. 87’s Gallery organ and the largest pipes of the Pedal Contra Diapason 32' in November 2008. The installation of the main organ began on 16 February 2009.

• • •

The Contra Diapason 32'

After the smaller pieces were removed from the truck, only the 32' pipes remained. Pipes down to 32' D were removed from the truck by hand, but the longest two were handled with the assistance of a forklift.

32' C was lifted by hand, and felted rollers were placed under it to allow it to move (relatively) easily.

The end coming off the tail of the truck still had to be lifted by hand, and manuevered to waiting wheeled carts on the sidewalk.

It’s a pretty long pipe.

A view of the nave after the truck is unloaded, as seen through scaffolding in the balcony. Construction work was underway at the church during the installation process—you can see the steel framing for the choir risers at the front of the church.

The largest of these wood pipes is 32' F#.

Because the 32' pipes are placed on either side of a large chimney, the largest pipe was the first to be put up—trial by fire.

“Those who are about to lift salute you.”

The Dobson crew before CCCC makes its ascent (from the right):

Bob Savage, Dean Heim, Donny Hobbs, Kent Brown, Abe Batten, John Streufert, John Panning, Jon Thieszen, with Lynn Dobson behind the camera.

A strap was run along the length of the pipe, and another around the body of the pipe at the top. The end of the pipe rests on a wheeled cart.

As the top is hoisted, riggers keep the bottom moving toward the scaffolding.

The riggers have to steer around a carved wooden modesty screen that can’t be moved.

32' C is now vertical.

Once upright, the pipe is manuevered around the scaffolding to stand on the floor below its ultimate location, and the straps are transferred to a second winch located above the windchest.

This single strap carries the entire 950-pound weight of the pipe.

Floating up to its final location.

Almost home.

The C-side after all pipes are installed. These eight pipes alone weigh about 3,500 pounds.

Both sides installed.

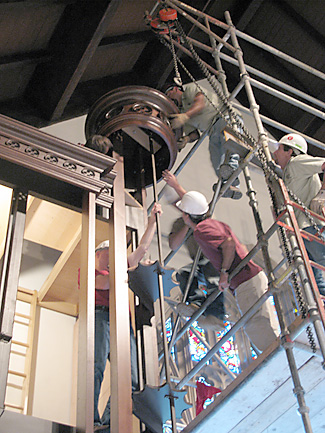

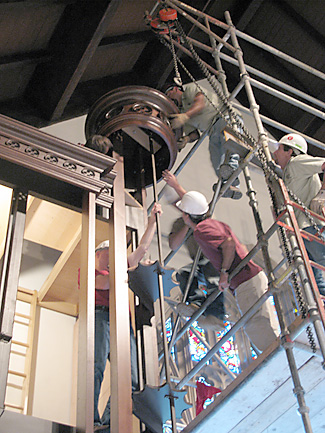

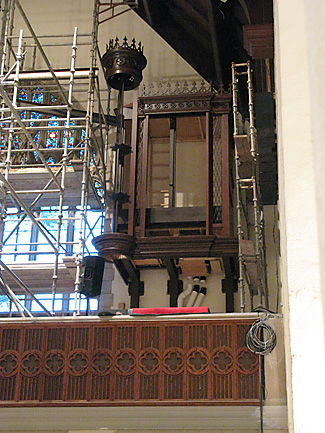

Scaffolding has been erected to hoist parts of the Gallery organ up to the balcony.

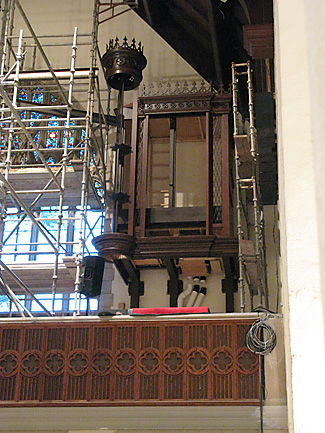

Steel members allow the organ cases to cantilever over the floor.

Work on the C-side case started first.

Raising the tower top.

Halfway there.

The top is supported by two case posts only 90° apart, and a steel post that is incorporated into the support system (or “racking”) for the façade pipes.

The C#-side case with its crown.

At the end of a long day.

The Gallery cases are almost completed. All that remains are the swell shades and C-side façade pipes