Setup of Main Organ in Shop

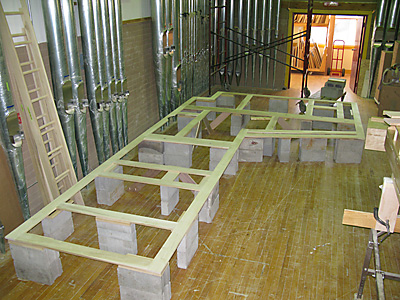

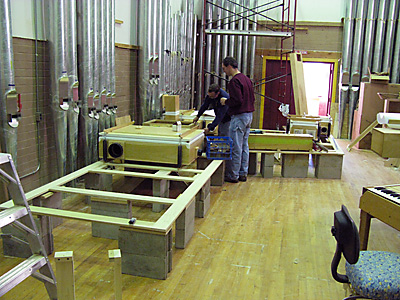

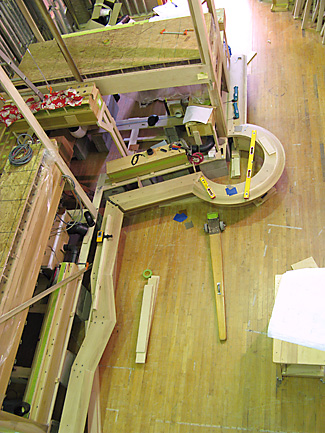

Now that the Gallery Organ is out of the shop, setup of the main organ is underway in earnest. The two halves of the main organ are supported by steel platforms erected in the church; the left, or C-side, is visible here. The large mouldings of the cases will hang over the edge of the steel.

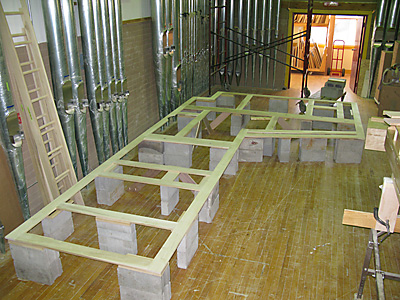

This is the floor frame for the C-side. To accommodate the large mouldings that overhang the steel, the floor frame is raised above the floor.

At the very lowest level are the reservoirs, which have a combination of springs and weights.

This area is also home to small windchests, left and center, that feed the Festival Trumpet and some of the façade pipes.

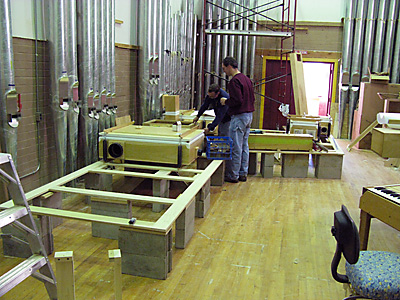

Next up: supports for the main slider windchests.

The Swell windchests (behind the ladder) are in place, and the vertical structure for the Great windchests have been set up.

Hoisting the Great reed windchest (16', 8' & 4') into place.

A view of the two levels of the Swell division. A corner of the upper Great windchest can be seen on the left.

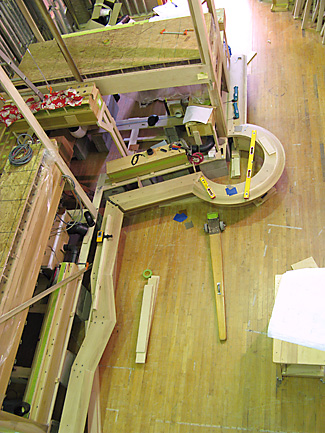

The constituent parts of the impost moulding are laid out around the organ. These will sit on the steel shown in the first photograph above.

To level the impost, a rotary laser is used. It projects a perfectly horizontal green laser beam 360° around the room.

It strikes everything in the erecting room...

...including a specialized laser detector that Dean is using to see how much the impost moulding must be shimmed to make it level.

With that information, Randy and Dean fit shims underneath the impost.

Once the impost is level, the façade posts can be installed.

They are temporarily braced until the tower top is installed.

The block for one half of the Festival Trumpet is installed to the left of the corner tower.

Mouldings at the top of the case are being put up.

The largest pipes of the full-length Basson 16' stand unmitered at the rear of the Swell, taking advantage of the room at the back of the double-height swell box.

Swell shades in place. They are butcher-block construction to prevent warping. This is important, because even a small amount of warping will keep all of the shades from closing fully, ruining the effectiveness of the swell.

John solders hooks on the back of a façade pipe. The largest pipes have hooks on three levels.

Kent fits decorative boards over the façade pipes.

A view of the pipeshades and tracery at the top of the case.

Pat fits pipeshades to one of the tower tops.

The music rack is being mounted to the console. After this, the console will be stained and lacquered, and the drawknobs and electrical components installed.

Now that everything for this part of the organ has been set up, the process goes into reverse. Here Kent and Randy are removing roof panels that Dean then lowers. They’ll then be sanded, stained and lacquered.

It always comes down faster than it goes up… Pieces are marked as necessary to insure proper re-assembly in the church, and screws and other hardware are put into labeled envelopes or boxes.

Now the process starts over for the other side.

Dean and Randy are assembling a stack of reservoirs at the rear of the C# side of the organ, which stands above the blower room in the basement.

The Positive and Solo are located on the C# side. The expression boxes for the Positive are in the center, with the Solo on the right. Both divisions have windchests on two levels.

The C# side block for the chamade.

Putting up large façade pipes requires many hands. This particular pipe is low A of the Pedal Octave 16'.

Now that parts of the console have been stained and lacquered, Bob can mount and wire the drawknob units.

Pipes and parts waiting to be loaded on the truck.

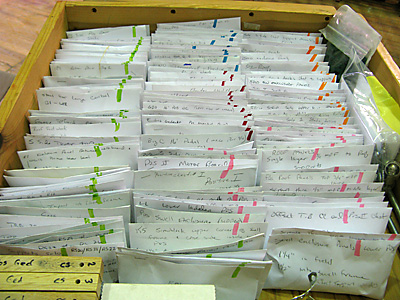

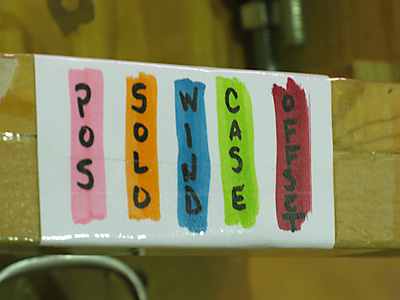

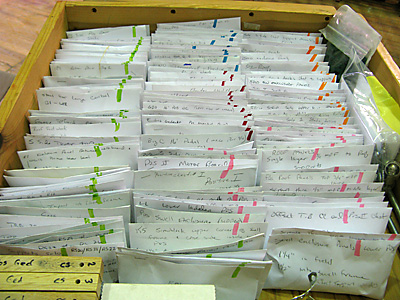

How do you keep track of thousands of screws?

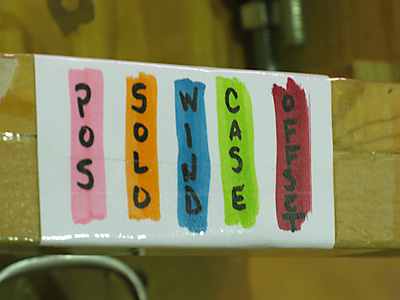

Color-code the envelopes. These are just for the C# side of the organ.

Another box of hardware. “Peanuts” is shop parlance for small wooden tabs that hold the raised panels in place.

The back end of the first of three semi trailers. There’s a lot of organ in there.

Back to Photo Albums