The entire organ stands on heavy steel beams so that it can straddle the historic monuments set in the Chapel floor.

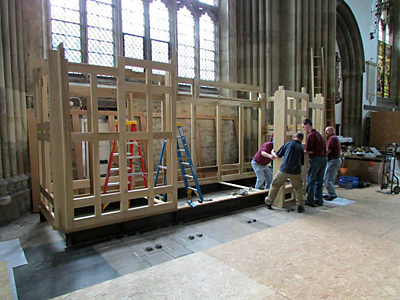

The lower case framework is erected.

The lower case of American white oak is installed.

The lower case comes together.

Hoisting the C# Pedal windchest into place.

Baseboard mouldings are installed at the rear of the organ.

Lynn Dobson in front of the organ at the end of the first three days of installation.

A well-deserved pint at Jude the Obscure Pub following the conclusion of the eventful first three days. From left: Lynn Dobson, Kent Brown, Jim Streufert, Abe Batten, Bob Savage, Dean Heim. Photo courtesy of Ben Nicholas.

The blowers stand on spring isolators so that no vibration is transmitted into the organ or Chapel.

Two smaller blowers are used because a single larger one would not fit within the close confines of the base of the organ. There is a small, third blower that raises the pressure for the Choir Major Trumpet 8'.

The Great, Choir and Pedal windchests are in place, and the structure for the Swell windchests, located above, is partially installed.

The three Swell windchests stand at this upper level.

The middle Swell windchest holds the treble pipes, notes 19-61.

The Swell treble chest is hoisted into place.

The second of three Swell windchests. This one is the C# bass chest, on which stand the even-numbered notes 2-18.

Heavy panels are carefully fitted around the Choir, so that its expressioin is as effective as possible.

One of the frames that makes up the back of the upper case is sent up.

The upper back of the case is in place, and the overall shape of the case can now be seen relative to the great west window.

One of the façade posts, waiting on sawhorses, is ready for hoisting. It is approximately 26' long and made of solid American white oak.

The post in place.

Dean Heim unpacks some pipes of the Great Bourdon 16', which stand on the outside of the case.

The first of the decorative grilles is installed.

Above the grilles is a toeboard for some bass pipes of the Great Bourdon 16'.

The pipes are painted vivid colors, characteristic of Medieval Gothic architecture.

The swell box is the full width of the upper case, so the swell shade front is equally wide and built in three sections.

The middle section of the Swell shade front is readied for hoisting.

The swell shade frames: Choir below, Swell above.

Inside the Swell.

Two of the reservoirs, carefully taped up to seal out dust and dirt in shipment.

The main horizontal wind trunk is installed.

Visible through the scaffolding is the CC Pedal wind trunk, which snakes its way around under the cantilever.

The console platform stands on its own steel beams.

A steel railing made in Oxford is fitted.

The electronic controls for the slider motors.

A façade post is readied for hoisting.

Façade post set in place.

A number of fretsawn grilles have polychromed edges. The front face is finished like the rest of the case lumber, but the edges are painted vivid colors. When seen straight on, the color is hardly visible but becomes more noticeable as one moves to the side.

The pipe shade of the center tower. "MC" on the left refers to Merton College, which the dates 1264-2014 refer to the 750th anniversary of the College’s founding.

Dentillated mouldings are fitted at the top of the case.

The roof above the center tower.

The center tower with its curving, prow-shaped crown.

It’s beginning to look like a proper organ case.

The console chassis, which contains the mechanisms for the couplers, is set into the organ.

Mechanical key action parts are installed behind the console chassis.

Unpacking façade pipes. While all of the interior pipes of the organ were made by us or A.R. Schopp’s Sons of Alliance, Ohio, no American pipemaker makes polished tin façade pipes. Those for Merton College were crafted by Aug. Laukhuff of Weikersheim, Germany, and shipped directly by truck to Oxford.

Three of the façade pipes are embossed.

The embossed pipes also have flame-shaped lips. The lips of all façade pipes are gilded with 22K gold leaf.

While the largest parts of the organ were raised by a hoist, the façade pipes were put into place entirely by hand.

All but the six largest façade pipes (16' C - 16' F) are in place.

Voicing façade pipes.

Bill Ayers voicing 16' F.

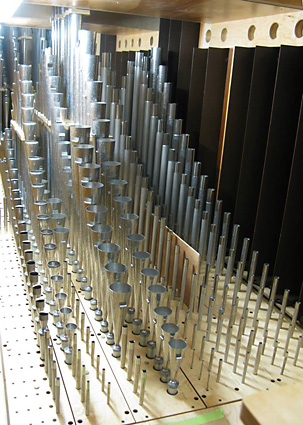

Pipes of the Swell.

The Swell reeds: Double Trumpet 16', Trumpet 8', Clarion 4', Hautboy 8' and Vox Humana 8'. Both Trumpet and Clarion have harmonic-length treble pipes.

The reed voicer’s humble throne: a packing blanket on an overturned five-gallon lacquer bucket.

Pipes of the Choir.

The voicer’s view of the altar over the roof of the Swell.

All finished: the container loaded with all of the empty pipe trays and crates, tools, scaffolding, and everything else required to install the organ.