Opus 89, 2010

Setup Photos

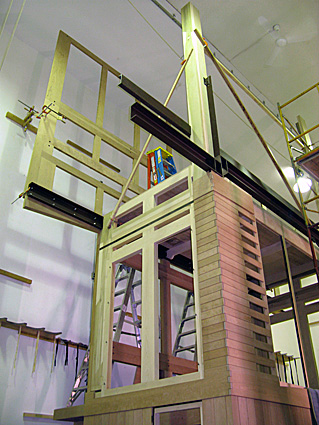

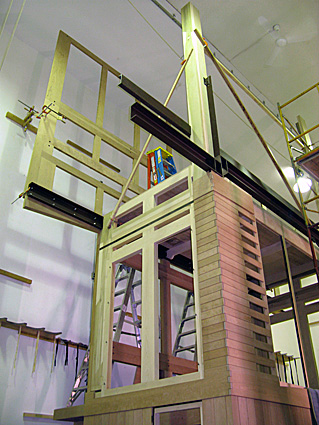

Because the height of the organ is about 25' taller than our 32' erecting room, setup of the organ in our shop will occur in two phases. First, the lower part of the organ, housing the Great and Choir, will be erected. After all work on that part of the organ is complete, it will be disassembled. Then, the upper part of the organ, which contains the Swell, will be set up. The Pedal, which stands behind the main case, will be set up separately.

This is a view of the lower case, looking up to the level of the Great windchests. The Choir is located below the Great.

The entire weight of the organ is carried by the four corners of the case. The case lumber at the bottom is 7 cm thick (about 2-3/4"), and the interior poplar corner post is also 7 cm thick, making for a total of about 5-1/2" of solid lumber. Thickness of the case lumber decreases as the organ rises; at the top, the lumber is 2.5 cm thick (1").

While wood works well in compression (i.e., as a load-bearing post), a wooden beam would have to be very large to carry the weight of the organ’s cantilevers. For this reason, we use steel horizontals that rest on the wood corner posts.

Dean, Randy and Kent install the Choir rollerboard.

While Dean and Kent hold the ends of the rollerboard, Randy installs the screws that hold it to the Choir windchest.

Parts waiting to be installed in the organ.

This isn’t distortion by the camera—the wooden frame in front of the Choir really is bowed.

It’s a long way up...and the top of this ladder is only at the level of the Great, in the middle of the organ. The Swell is located above that yet.

The Great windchests, with the solenoids that move the sliders located in between.

Some of the largest Choir bass pipes and their upper racks are installed. The tin pipes in front belong to the Salicional 8'.

The C#-side case bracket.

A set of façade pipes, the Pedal Octave 8', will hang upside-down in front of the Choir division.

Racking façade pipes. The upper group of pipes belong to the Great Principal 16'; the inverted pipes are from the Pedal Octave 8'. The largest inverted pipe is 8' G#.

The inverted pipes hang in front of the Choir swell shades. Their feet are not situated in a straight line, but follow a subtle curve, slightly deeper in the middle.

The console is detached from the main case, so the trackers pass under the floor in a chase that is cast into the concrete. This organ, like all our recent mechanical action instruments, uses carbon fiber rods for the trackers. Because of the size of the chase, the frames that support the trackers must hinge to fit into the chase, and into the organ.

Bob and Randy guide the tracker run into the organ. The black carbon fiber trackers can clearly be seen. Unlike wooden trackers, bending them in this way does no harm to them whatsoever.

Randy, Bob and Randall attach the end of the frame to the console chassis. (Apparently it was plaid day when the photo was taken.)

Pat makes sure that the other end is properly aligned within the case. You can see the black vertical carbon fiber trackers here.

The top-most tracker run is put into place.

Like the others, this run is hinged in the middle.

Donny, Art and Bob insert the run into the case.

There are six levels of trackers under the floor: Pedal, Choir, Swell C#, Swell CC, Great C#, and Great CC (from bottom to top).

A view of the Choir rollerboard with the Choir reservoir inflated behind. Passing between the rollerboard and the back of the case are the carbon fiber vertical trackers for the Great and Pedal

The pipeshades in front of the Choir are freely sawn strips of cherry.

The organ and its console chassis just fit in the erecting room.

The lower case has been disassembled, and now the upper case has been set up. In the center is the block for the Horizontal Trumpet 8'.

A view of the walkboard behind the Great.

The University of Tampa

The University of Tampa